Technologies

Three printing technologies under one roof

Digital printing became the third printing technology back in 2001

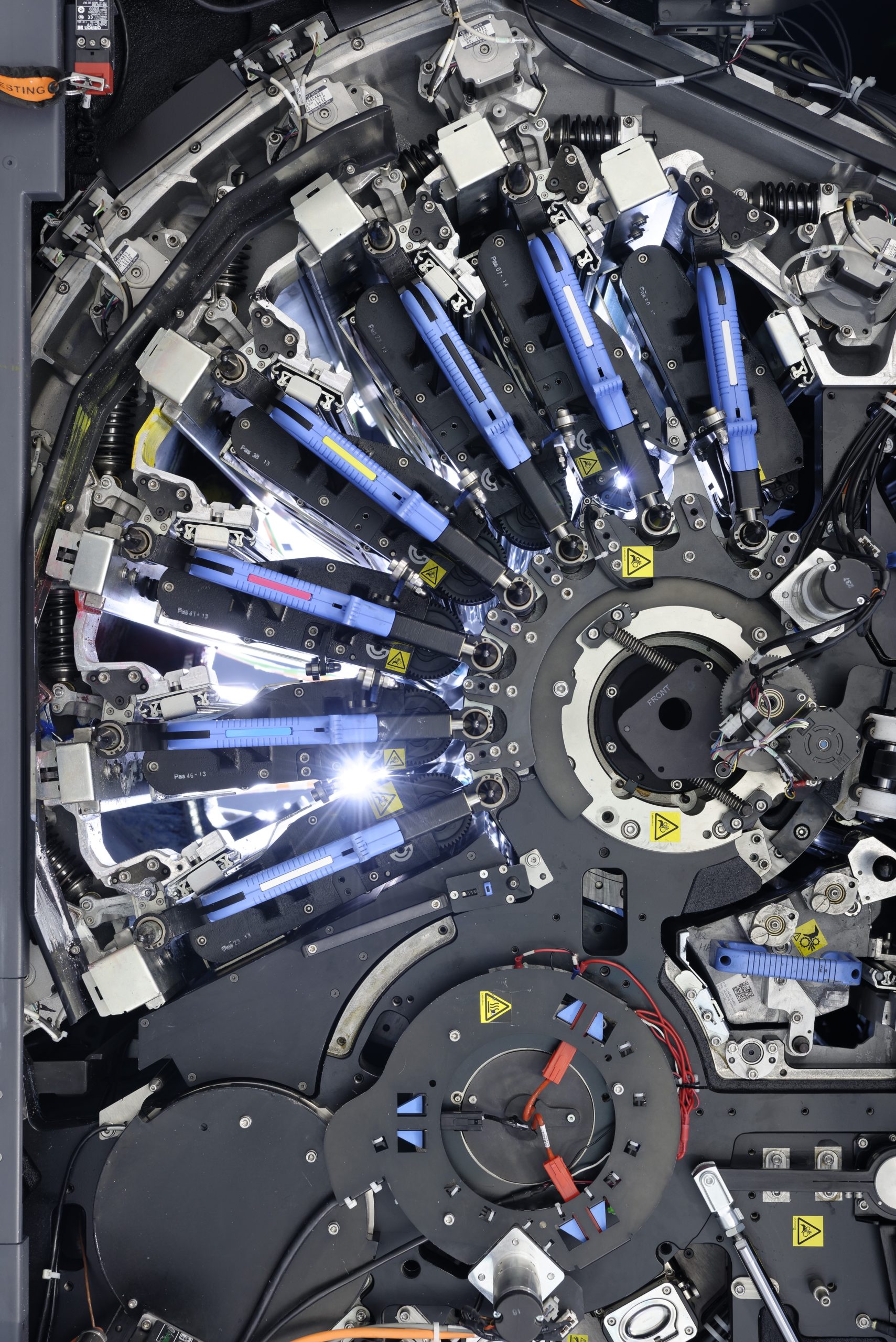

DIGITAL PRINTING

- HP Indigo 25K

- For industrial applications and customized packaging

CMYK basic colors plus white and special colors

Resolution: 812 dpi at 8 Bit (standard)

Mashine print width 746 mm (untrimmed)

Substrates: all commonly flexible packaging industry materials

Sterilizable and pasteurizable applications

With metallic effect

Shortest "time to market"

Flexographic Printing

- Rational production of product lines thanks to quick text and color changes

- Combining the benefits of two printing technologies

Up to 9 colors (8+1) with integrated gravure printing unit

Opaque and high-density colors, special coating applications

HD quality with 100% visual inline control system

Gravure Printing

- Rational production of product lines with maximum printing quality thanks to quick text and color changes

- Efficient for small and large print runs thanks to the latest technology

Up to 10 colors

Top quality printing

Coatings

100% visual inline control system

LF/LH Laminating

- Solvent-free or solvent-based laminating depending on the filling material and stability process

- Combining plastic, paper, aluminum, metal Foil, barrier coatings and fluid media

Solvent-free

Solvent-based

2 to 4-fold lamination

Cutting

- Laser scoring or laser perforation

- Can be delivered in roll form or as pre-made bags

Laser scoring for controlled opening

Laser perforation for package ventilation

CONSULTING

We offer quick, personal consulting

Over 20 years ago, we were pioneers for environmental sustainability in the flexible packaging industry – and we have been continuously expanding our knowledge ever since.

Also interesting